What are the Alternatives to Gas Boilers?

Blog As a result of a potential ban on gas boilers by the Government of the UK, many homeowners are

A boiler makes life easier when it’s cold outside and we need hot water. However, like all human inventions, boilers also need periodic maintenance. Over time, they start exhibiting abnormalities which require immediate attention. Low pressure is one of the main problems with contemporary boiler systems.

Your boiler will typically exhibit low pressure during periods of prolonged inactivity, such as the summer. Let’s learn what is boiler pressure and its causes of low boiler pressure.

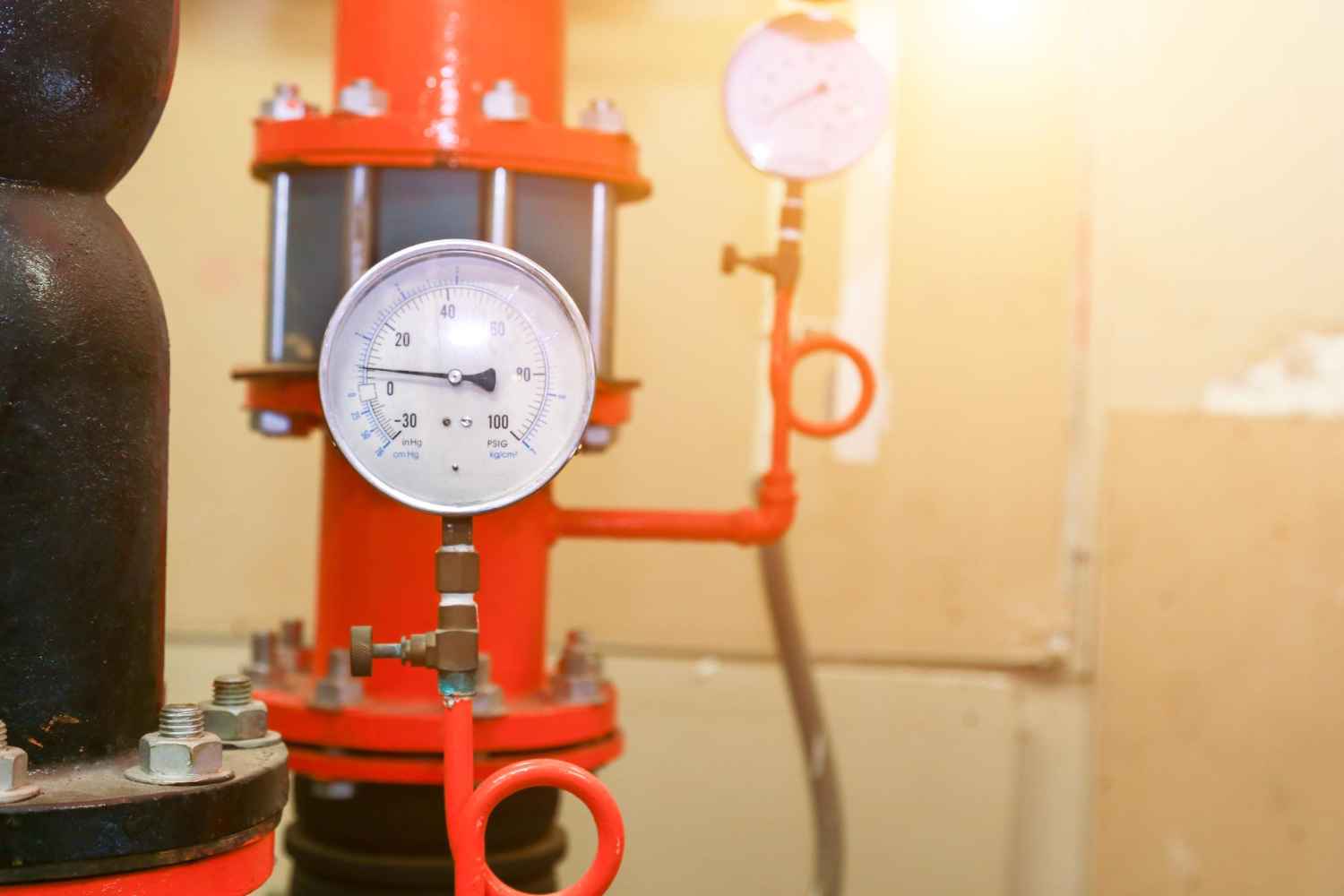

It is the measurement of the water pressure in your boiler and heating system. The pressure gauge can be used to check the pressure in your boiler. This gauge shows the pressure inside the system to find any leaks or pressure decreases.

When a boiler is turned on, its pressure gauge typically reads between 1 and 2 bars. Depending on the boiler manufacturer, the precise suggested pressure level will change, but generally speaking, 1.0 to 2.0 bar is the ideal pressure for a boiler.

Low boiler pressure refers to the phenomenon of the boiler’s pressure being lower than the required levels. It is a very common issue for home heating. Low-pressure boilers are different from high-pressure boilers, as the latter have a higher pressure and temperature.

These boilers usually heat their water to a maximum temperature of 250°F, and the steam pressure rarely exceeds 15 pounds per square inch (psi). A low boiler pressure is indicated when the boiler gauge reflects this condition. That is why if it indicates that the pressure is lower than the normal level, it can mean that there is a problem.

To determine if your boiler’s pressure is low, begin by consulting your boiler manual and examining the dial’s markings. The manual typically outlines the recommended pressure parameters, often depicted by two lines on the dial.

If the gauge reading or needle falls below this specified range, it indicates low pressure. Specifically, if the gauge indicates below 1 bar when your hot water is running or when you activate the central heating, it signifies inadequate pressure.

In such cases, the boiler pressure needs to be increased, ideally to a level between 1 and 2 bars, to ensure optimal functioning.

Maintaining adequate boiler pressure is vital for efficient heating and consistent hot water supply. When the pressure drops below the recommended level, the boiler operates inefficiently, leading to increased energy consumption and higher costs.

Low pressure could indicate reduced water circulation, necessitating the boiler to exert more energy to heat and distribute water effectively. Regularly monitoring boiler pressure is essential to optimise heating efficiency and ensure cost-effective operation.

Low boiler pressure can result from various factors:

When components inside the boiler deteriorate or become loose over time, boiler leaks may result. Boiler parts can loosen with age and cause the system to lose pressure if they are not repaired periodically. Usually, these leaks will manifest as a visible drip coming from the boiler’s underside.

The boiler needs to be pressurised again for your central heating system because bleeding radiators can drop boiler pressure if that is the case for you. The ideal boiler pressure range is 1.0 to 1.5 bars. However, if the amount is lower, then you’ll have to increase the pressure.

If the pressure relief valve is unable to release water or is not in the correct position, the pressure in the water tank will be reduced.

If the overall pressure suddenly falls dramatically, yet there is no apparent leak, consider how the expansion vessel is functioning. Refilling the central heating system would be inappropriate since this would lead to an undesired pressure drop and possible damage and failure of the system without an expansion tank.

The corrosion inside the boiler is another possible cause behind the low pressure. The presence of corrosive elements within the boilers varies according to the concentration of oxygen and the pH of the solution, along with the amount of water impurities that lead to the degradation of the metal components and weaken the structural integrity of the boiler. It is also a waste of energy as it reduces the efficiency of the boiler unit and, if not kept under control, leads to safety hazards.

Using inferior pressure gauges on boilers would inevitably create incorrect readings and complications in the system, like false alarms or suppression of a real problem. It is important to plan this quickly since the pressure of the boiler has to be constantly monitored.

Low boiler pressure might indeed arise from incorrect boiler installation. Inadequate system setup or wrong sizing of the various components will result in inefficiency in water circulation, which leads to a pressure drop. It is important to fix errors that occur during the installation process to ensure that the boiler works well and the pressure in the system is at the right level.

It is, therefore, important to have an understanding of the exact reason for low boiler pressure in order to carry out corrective actions.

Below are some initial DIY steps that you can take to fix the problem:

By following these detailed steps, you can effectively address low boiler pressure and restore optimal functioning to your heating system.

In conclusion, hot water and warmth are important, and pressure is crucial for boilers’ proper operation.

Inadequate boiler pressure is a combination of leaks, poorly functioning parts, or poor installation, which results in higher energy usage and decreased performance. Improper action towards boiler pressure problems can lead to inefficiency and discomfort within the home as well as potential cost concerns.

Blog As a result of a potential ban on gas boilers by the Government of the UK, many homeowners are

Blog Handling a blocked toilet can be chaotic and stressful. Our aim is teaching you how to unclog a toilet

Blog Your boiler is essential for your home, providing warmth in winter. It also offers hot water to wash your

If you’re facing any issues or need our assistance for anything, please don’t hesitate to reach out to us.

Reviews